The Ditching and Aftermath

Extract from the July 1996 edition of Australian Aviation, and I thank Jim Thorn and Macarthur Job for their help in publishing this article.

Air Safety as told to Macarthur Job.

The report by Bureau of Air safety Investigation, released earlier this year, on the ditching of a chartered DC-3 in Botany Bay on April 24, 1994, has generated a good deal of controversy amongst those in the industry still familiar with this extremely well known and much loved veteran aircraft type. As a sequel to the precis of BASI’s investigation report in our June issue, Captain Rod Lovell, pilot in command of the flight, now gives his own first hand account of the events surrounding the ditching.

In preparing for this overwater flight to Norfolk Island via Lord Howe, I tried to cover every facet of the operation – in fact more planning went into it than any other I had done in my entire flying career.

All requirements were studied and complied with, International Relations Branch was notified of the intended flight, permission was obtained to park the aircraft overnight at Norfolk Island, and Customs and refuellers at both Lord Howe and Norfolk were alerted. Single engine fuel (1955 litres/430 imp gal) was to be carried on both flight sectors.

On the afternoon before the flight (Saturday, April 23) another professional pilot and I spent a couple of hours at the aircraft (parked on the grass at Sydney Airport’s Eastern Park), with the flight attendant, going over safety equipment and ditching procedures. These included use of life jackets, likely ditching damage to the aircraft, liferaft launching, passenger and crew evacuation, equipment to be taken in liferafts, discipline, keeping the liferafts together, and the use of the ELB.

The day for the flight turns out beautifully – Wing Commander’s weather! Our ETD from Sydney is 9am and, with all preflight planning completed, including weather forecast and Notams, I lodge our international flightplans before leaving for the airport in company with the supernumerary pilot – he is accompanying us to gain experience in remote island operations.

At 7.30am when we arrive at the aircraft, the first officer is already there and has begun his preflight preparation. While I inspect the safety equipment aboard the aircraft, he completes the prestart checks, starts the engines and carries out satisfactory runups on both.

At 8.30am we taxi the DC-3 to Hawker Pacific’s apron where we load the baggage and freight, and the ground agent completes the passenger manifest. I have already completed a load and trim sheet because the company chartering the aircraft faxed me the passengers’ names and dates of birth a couple of days earlier. So using data from Civil Aviation Advisory Publication No 235-1(1) Standard Passenger and Baggage Weights which were incorporated in our Operations Manual, I was able to calculate their approved weights and determine the load distribution in advance.

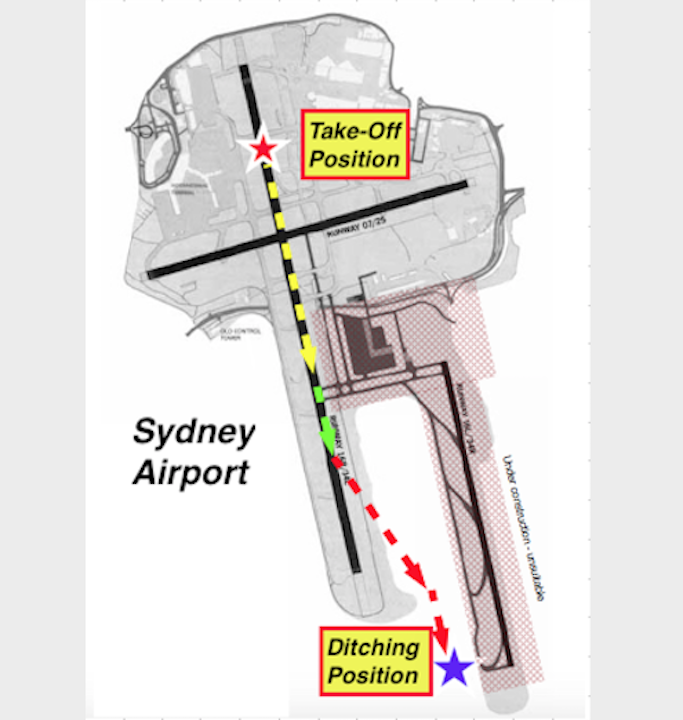

The passengers go aboard and we start the engines again. I am in the left hand seat, with the first officer in the right hand seat. Our supernumerary pilot removes the undercarriage pins, climbs aboard, and on the stroke of 9am we taxi out. The first officer is to carry out this takeoff and, as instructed by the Tower, he taxies for a B3 intersection departure from Runway 16.

We are cleared for takeoff a few minutes later, and the takeoff roll seems perfectly normal, as does the liftoff (I clearly remember the moment because Cathay 101 was cleared to land just as our main wheels lifted from the runway). As soon as we are safely airborne and have a positive rate of climb, I select the undercarriage up.

But at about a height of 200 feet, with our airspeed in excess of 100 knots (185km/h), the first officer calls the port engine has failed. Engine instruments confirm this (contrary to the impression conveyed by the BASI report, it seemed to be a total failure – just as though the fuel had been cut off), and I feather the propeller in accordance with the Emergency Procedures Checklist in the Operations Manual, visually checking the propeller as it stops. It appears to be in the feathered position.

At this stage we are still at about 200 feet, slightly to the left of the runway centreline, and I fully expect us to continue climbing. But we’re not – and the airspeed is beginning to decrease as well! With takeoff power of 48 inches of manifold pressure and 2700 RPM (1200bhp) on the starboard engine, I cannot understand why the aircraft is not performing as it should – even with METO (maximum except takeoff) power of 1050bhp, we should be able to climb. I tell the Tower we have a problem, but at this stage, I still intend to climb and return to the airport for a landing. But it doesn’t take me long to realise the DC-3 isn’t going to stay in the air!

Three options immediately present themselves:

- Land straight ahead on the remaining runway. Can I get both main wheels down and locked in time to land on the remaining runway without nosediving over the far end? Because there is no mechanical connection between the hydraulically operated undercarriage mechanisms of the DC-3’s two main legs, one wheel will nearly always retract or extend before the other. Even with two engine driven hydraulic pumps working normally, it takes time to complete the full retraction or extension cycle. Right now we are reduced to only one hydraulic pump, so it will take considerably longer. In the water beyond the end of the runway are large concrete blocks, arranged so as to break the incoming sea swell and protect the seawall. If we overrun the end of the runway on to the concrete blocks, the aircraft structure will almost certainly be torn open, with the real possibility of rupturing the fuel tanks and an explosive fire. Its not an option!

- Try and land on the new parallel Runway 16 Left, which extends further out into Botany Bay. But we are not aligned with it, and the aircraft does not have the performance to reach it. Even if we could, it is still under construction, with equipment, vehicles and mounds of sand littering its entire length. Again, it’s not an option! The aircraft’s altitude and airspeed are still decreasing and it’s obvious my one remaining option is a controlled ditching. As the airspeed falls towards 80 knots (148km/h) I take over from the first officer, extremely conscious of the fact that I must maintain control of the aircraft – to lose control would spell disaster.

Determinedly, I remind myself of my responsibility for the safety of my passengers and crew – all too conscious of the tragedy that overtook a Beech Super King Air in exactly this situation at Sydney Airport in 1980, when the pilot attempted turn back after an engine failure on takeoff, but crashed into the Runway 16 seawall with the loss of all on board. I resolve that it’s not going to happen to us! - I think again: Why isn’t the starboard engine producing full power? Ground effect also crosses my mind – why isn’t it helping us? Ground effect might well help us stay in the air by the time we’re down to 20 feet over the water. But what happens then if the speed still continues to decrease? The good book says Vmca is 73 knots (136km/h) – and I don’t want to get near Vmca at only 20 feet. Losing directional control in those circumstances could mean the port wing dropping and hitting the water and the aircraft cartwheeling in – certainly resulting in serious injuries and quite possibly loss of life.

It is a strange feeling to face a deliberate ditching, knowing it means sacrificing the aircraft. I experience a fleeting wave of fear – but it is immediately suppressed by professionalism continuing to dictate that the safety of all on board is all important. And a controlled ditching is the only safe option!

Furthermore, if we ditch close in to the shore, there are plenty of small craft nearby to come to our rescue. On the other hand, if we did succeed in staying in the air for a time, but were then forced to ditch, we may be on our own. Having accepted the decision, the determination to succeed with minimum injuries becomes paramount.

I call for full flap, retard the power on the starboard engine, and, just above the flat calm surface of the bay, flare the aircraft for impact. We are now abeam the southern end of the new runway, only about 70 metres out from its western seawall, and the airspeed is back to about 60 knots (112km/h).

I am “happy” with this, conscious at the same time that the aircraft “perspective” seems extremely low. A moment later we splashdown tail first and in an instant, as the nose pitches down hard, it seems like hitting a wall. As a great wave of water surges up and over the nose, the first officer and I are thrown forward, our heads striking the windscreen. (Our shoulder harnesses are not fastened – it is impossible to reach the undercarriage handles wearing secured shoulder harnesses.) At the same time the aircraft slews around to the right, probably as a result of the drag of the still rotating starboard propeller, coming to rest slightly nosedown in the water on a westerly heading. A total of 46 seconds have elapsed since the port engine failed.

Momentarily in the cockpit there is bedlam – the fire warning bell is ringing and the undercarriage warning horn is blaring. I silence the fire warning bell with its switch, but am frustrated to find that even turning off the battery master switch off fails to silence the continuously sounding warning horn. The first officer yells that the electrics have shorted out.

I swing around to look back into the cabin to check how our passengers have fared in the ditching. I expect to see carnage – but instead I see the passengers standing up and calmly putting on their life jackets. I experience an overwhelming feeling of relief!

The supernumerary pilot immediately goes back to help the passengers and ensure they are donning their lifejackets correctly. At first the aircraft seems to floating well – looking out my port side cockpit window I can see the engine cowls are either torn back or missing, but the top of the wing is well out of the water. Soon boats are converging on us from everywhere and, leaning out to signal to the nearest, I suggest to the first officer that we take a line through the cockpit’s sliding side windows and have the aircraft towed to shallow water.

But it is soon obvious that water is entering the cockpit rapidly from below the floor, and it is extremely doubtful if there will be time for this before the DC-3 sinks. Clutching the DC-3 red flight folder, the first officer climbs out through the overhead hatch, while I go back into the cabin to supervise the evacuation with the supernumerary pilot.

The flight attendant, who has been injured in the ditching impact, has already been taken off in one of the inflatable liferafts, and transferred to one of the nearby boats. The passengers, all wearing lifejackets, are also evacuating the aircraft through the main door in an orderly manner and are being quickly picked up by the various small vessels now standing by.

I am becoming concerned at the rate at which water is now covering the cabin floor, and I urge those still on board to hurry. Meanwhile, the first officer has walked along the top of the fuselage and on to the tailplane where he is being taken off by a pleasure boat – without getting wet!

When I’m certain there is no one else left on board, the supernumerary pilot and I also jump into the water from the rear door. Although we insisted that the passengers were wearing lifejackets before they left the aircraft, we flight crew were not (to be chastised tongue in-cheek by the investigators later!), but we quickly climb into a liferaft.

Nine weeks after the accident I was to experience the most shattering moment of my professional flying career when the CAA (as it was then) suspended my licence, I believe quite unjustly. I cannot emphasise strongly enough the depression and anger I felt at the time. And these same feelings were rekindled recently when the Bureau of Air Safety Investigation released their official report on the accident. The following is a summary of what I believe to be injustices in the BASI investigation.

COMMENTS ON THE REPORT

Overall, I take great exception to the innuendo in the BASI report regarding my lack of professionalism. Throughout my flying career I have always strived to maintain a highly professional attitude and this flight was no exception. Some highly experienced and respected DC-3 pilots attest to my abilities in handling these and other aircraft.

The report’s coverage of the circumstances of the ditching are inaccurate, superficial and in certain areas, untrue. It is obvious that the flight operations aspects of the report were conducted without consultation with experienced and impartial DC-3 specialists. The fact that BASI did not carry out flight tests on a DC-3 of similar airframe and engine hours is but one indication of the investigation’s lack of objectivity.

Aircraft performance

Reporting a fatal engine failure on takeoff accident of a Piper Chieftain at Melbourne Airport, Aviation Safety Digest No 108/1979 described how the investigators found that although the aircraft was overloaded by 65kg (MTOW 3178kg) or 2%, this degraded its single engine climb performance by only “about 25 feet per minute”. However, they also estimated that, because the airframe had flown about 3400 hours since new, the degradation in single engine climb performance from airframe condition would have been a further 100 feet per minute. In addition, they stated that “the estimated effect of the lower than normal power on the left engine m this case was a loss of approximately 75 feet per minute rate of climb”.

By contrast in the case of my accident, despite the 40,000 hours plus which the DC-3 had flown in its 50 year life, the investigators totally ignored the likelihood of both airframe and engine degradation. The BASI report neither acknowledged the “tired” condition of the airframe, with its dents, chipped and flaked paint, misfitting doors, hatches and cowls, nor the considerable additional parasitic drag induced by aerials, oil drains, a huge bulbous viewing window and other nonstandard fittings protruding into the airstream.

The airframe abounded in dents and other small imperfections – the main entry doors did not close flush with the fuselage and the rough surfaced wing root area (used as walkway, on top of the fuel tanks) had begun to peel away. The control surfaces, being fabric covered rather than metal, could also have been a little out of “true” as a result of age. Both the aircraft’s 7.3 metre ailerons were in fact so mis-rigged that a much larger than standard fixed tab was fitted to the port aileron. Even so, about eight units of aileron trim were required to maintain wings level.

It appears to me that the combined effect of these deficiencies alone could have rendered this particular DC-3 incapable of climbing on one engine. Moreover, the investigation produced no evidence to show that the starboard engine was in fact producing full power. The report states that the port engine (operating on a 100 hour extension to its TBO) was suffering from “mechanical distress” prior to the accident. But as the starboard engine had flown even more hours since its last overhaul, it also seems unlikely that this engine was still at the peak of its performance. Indeed, the BASI report said that the electrode gap settings of the spark plugs from both engines were “inconsistent”, with the majority of plugs showing evidence of electrode wear beyond normal life”, and some plugs breaking down electrically on test.

The instrument indications of full power on the starboard engine during our attempt to climb are not necessarily proof that full power was being delivered. Pratt & Whitney state in its Aircraft Manual of Engine Operation, that on an R-1830 radial engine, it is possible to have two cylinders malfunctioning, yet still have the indications of takeoff power. Not only did the BASI report fail to make any acknowledgment of this possibility, but the investigators themselves made no real attempt to determine the true operating condition of the starboard engine at the time of the ditching. Instead they allowed it to remain submerged on the seabed of Botany Bay for nine weeks before raising it for examination. Inevitably, after this length of time in salt water, it was in no condition to be tested to determine its power output during the emergency.

The BASI report also describes the increased drag induced by the failure of the port propeller to feather completely as “negligible”. A retired aerodynamicist I have consulted believes the use of the word “negligible” in this context is irresponsible, and that considerable testing would be required to determine the actual reduction in single engine performance. The US Navy publication Aerodynamics for Naval Aviators contains a graph which shows that the parasitic drag from the DC-3’s port propeller, stationary at 65° would actually have been a little more than that of a windmilling propeller at the same angle!

The BASI report places considerable emphasis on DC-3 test flight results obtained by the RAAF’s ARDU and by TAA nearly 50 years ago. These tests were performed on new, well maintained aircraft and flown by test pilots. Even then, the single engine performance figures were, at best, marginal. Yet the BASI investigation used these 50 year old figures to claim that my DC-3 was capable of climbing at between 50 and 100 feet per minute. But even if this could have been achieved, such a marginal rate of climb would hardly have been enough to adequately clear Kurnell Oil Refinery on the other side of Botany Bay! And it certainly would have taken the aircraft a long way from available rescue facilities before it was safe to turn back for a landing on the airport, all the while relying utterly on the continuing operation of a high time engine at full power. In short, such a course of action would have progressively eliminated available options for a safe outcome. It was for these reasons that I made the decision to ditch early thus positioning the passengers close to an accessible rescue point.

The weight debate. Because I personally prepared the load sheet and subsequently supervised the loading of the aircraft prior to departure, I still firmly maintain that on the basis of the information available to me, the aircraft was not overloaded.

After the aircraft had been salvaged from the bay and moved to a hangar, BASI investigators weighed the passengers’ baggage, while it was still soaking wet, on an old set of analog bathroom scales on the hangar floor. When I questioned this at the time, I was told the results would be “factored” (whatever this meant). The report makes no mention of this procedure, nor of any action to check the calibration of the bathroom scales.

The basic weight of the aircraft, used for weight and balance calculations, is also in doubt. When it was last weighed in October 1992, an authorised person from Melbourne performed the work, using scales hired from the Roads and Traffic Authority, but which were not approved by the CAA. The weighing was conducted in the open rather than in a hangar, on uneven ground, and in the taildown position, all contrary to CAA requirements. The basic weight of the aircraft could thus have been in error, in which case the BASI calculated takeoff weight would also be in error

The first officer

The BASI report provides evidence that the CAA issued the first officer with an Australian Commercial Pilot Licence and DC-3 command type rating. I am then accused of not having verified the validity of this licence and endorsement. Yet this was a CAA dereliction – the CAA had approved the pilot to fly DC-3’s as pilot in command and as such I had no reason to believe he was not competent to fly the aircraft. I had in fact assessed his ability on previous check flights as above average.

At the time of the emergency, he was merely handling the controls while I maintained complete control of the situation. I was at all times in a position to take over, and did so at the appropriate time. The crew procedures during the emergency were the same as on any modern airline flightdeck.

I dispute the BASI report’s statement that “almost full right aileron had been used to control the aircraft”. The implication of yaw is overstated. The application of hard right aileron was transient only.

Performance charts

The operations manual we were using was approved by the CAA. I was never advised by the CAA to remove the charts PK16.1/l or PK16.1/2 from the company operations manual, either verbally or in writing, and I challenge the CAA and BASI to produce documentary evidence to the contrary. I have the letter in my possession that approved the operations manual and consequently the performance charts.

BASI had two years to investigate this accident. I had a mere 46 seconds in which to assess the situation, evaluate available options, make a decision, select a site, and carry out the ditching!

I vehemently deny I was in any way responsible for the accident, and I maintain I did the very best I could in the circumstances. With the benefit of hindsight, I would change none of my actions.

Indeed, I still derive immense satisfaction from the fact that I was able to carry out a successful ditching in which everyone survived.

I would add that a former RAAF Deputy Director of Flying Safety who sat in on my BASI interview, congratulated me on my cockpit resource management, saying it was the best example he had heard of.

If I had been aware of the conditions that brought about this accident, I would not have flown the aircraft on that flight or any other. Clearly the then CAA was extremely negligent in its surveillance of this whole operation particularly in allowing the DC-3 to continue flying when they knew the port engine was suffering “mechanical distress” – and with both engines on overhaul extensions.

I therefore take exception to the way I appear to have been made a scapegoat by both the then CAA and BASI. A more objective investigation would surely have concluded that the aircraft was simply old and tired.

As far as I am aware, this is the first major accident investigation involving a transport category aircraft in Australia for many years. Could it be that today’s Bureau of Air Safety Investigation is lacking some of the resources, maturity and professional impartiality that were so much the hallmark of major Australian accident investigations in years gone by?

Other Interesting FACTS:

Aircraft TTIS 40,195:05 hours

Left Engine TSOH 1,027:56 hours Right Engine TSOH 1,085:53 hours Left Propeller TSOH 550:25 hours Right Propeller TSOH 830:48 hours

At the time of the accident, both engines were operating on CAA-approved concessions to overrun the published TBO of 1,000 hours.

Initial inspection confirmed that the left propeller was at 65-66 degrees of pitch instead of the 88 degrees pitch of the fully feathered position.